Industries We Serve

Hospitals & Pharmaceutical

Wireless Communications

Industrial

Commercial

Utility

Transportation

Institutional & Educational

Entertainment & Media

Recent News

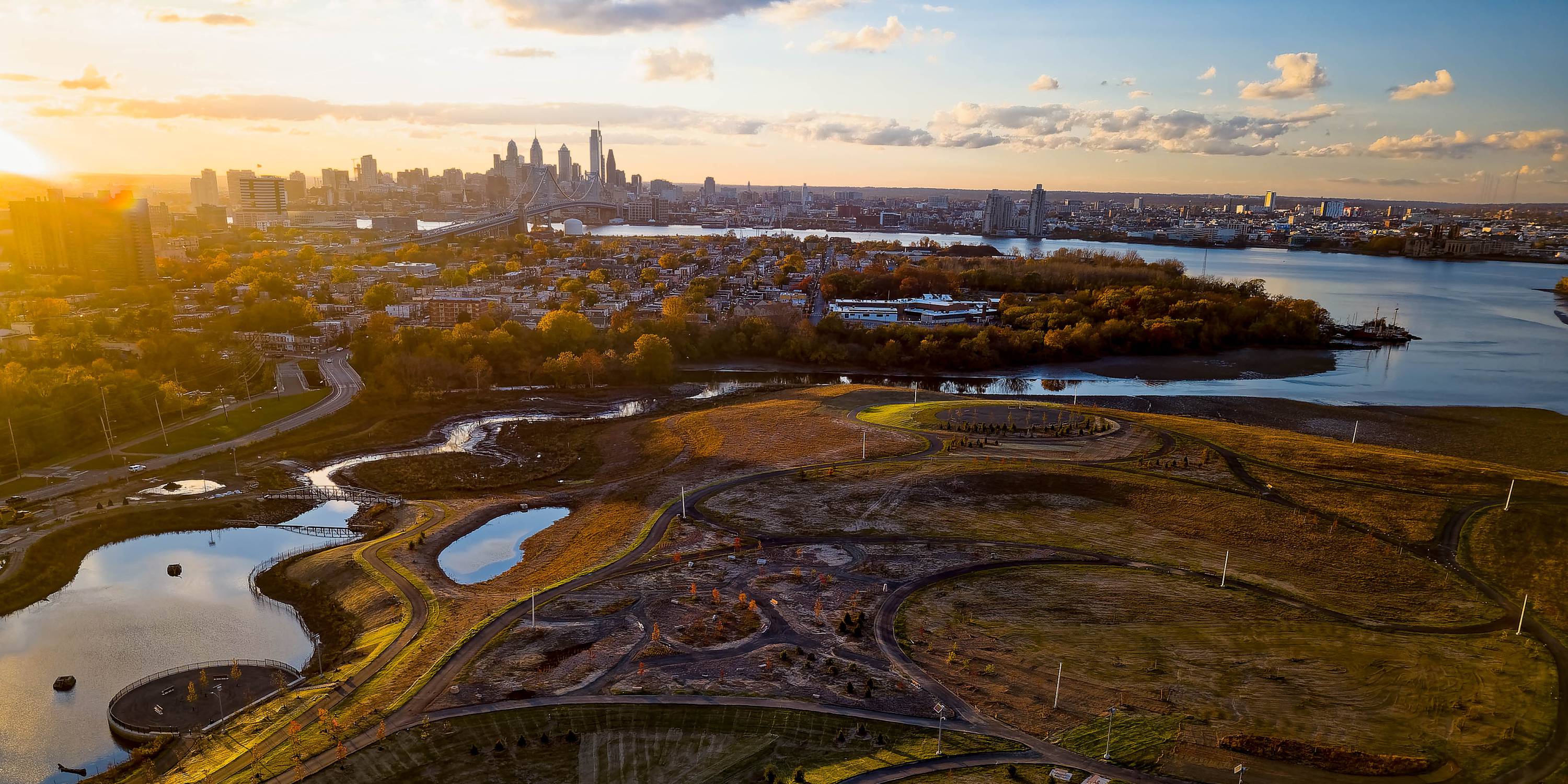

Philadelphia Street Lighting Project

Philly’s new energy-saving LED streetlights may reduce crime and fatal crashes. But what about light pollution?